Excellent quality Belt Weighing System - JJ-LIW Loss-In-Weigh Feeder – JIAJIA

Excellent quality Belt Weighing System - JJ-LIW Loss-In-Weigh Feeder – JIAJIA Detail:

Function principles

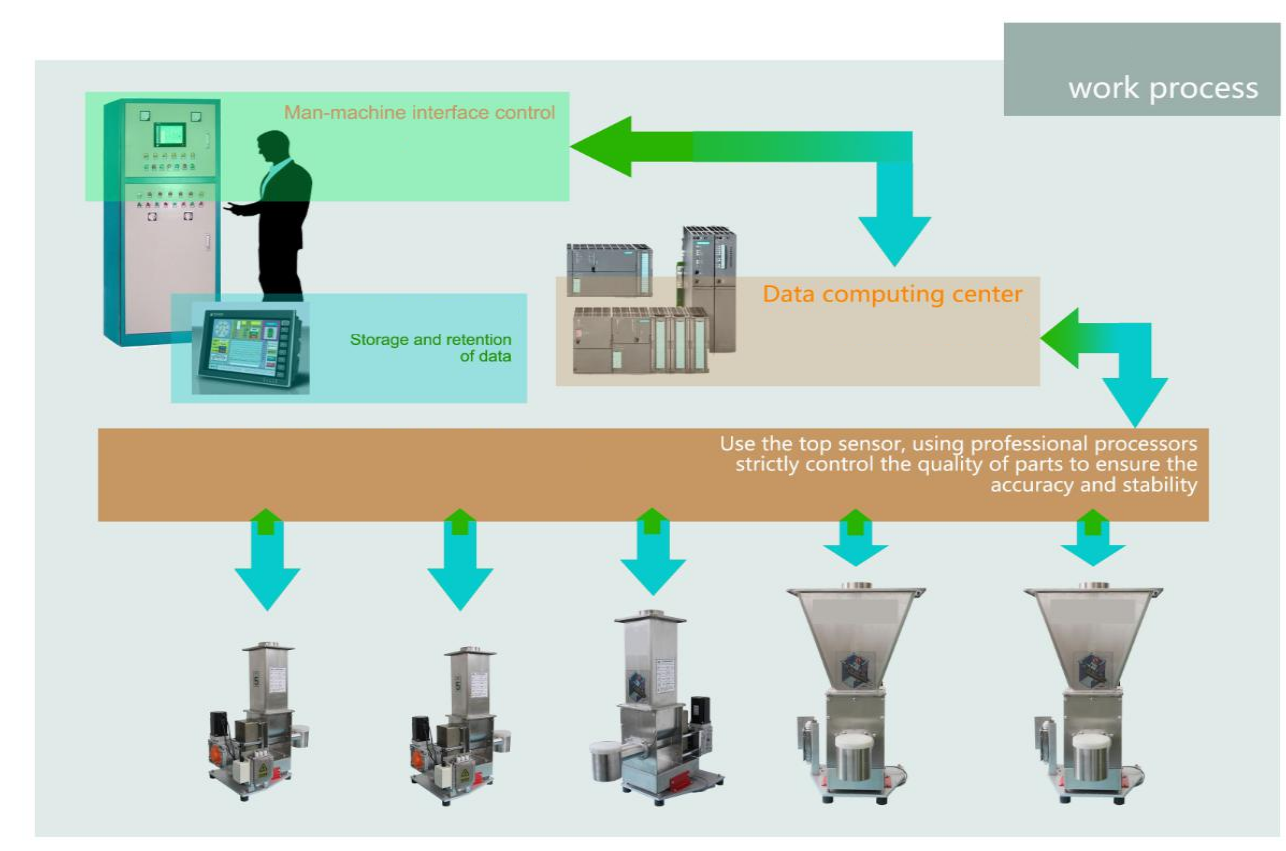

LIW series loss-in-weight flow metering feeder is a high-quality metering feeder designed for the process industry. It is widely used for continuous constant flow batching control and precise batch control process of granular, powder, and liquid materials at industrial sites such as rubber and plastics, chemical industry, metallurgy, food, and grain feed. LIW series loss-in-weight flow metering feeder is a high-precision feeding system designed by mechatronics. It has a wide feeding range and can meet a variety of applications. The entire system is accurate, reliable, easy to operate, easy to assemble and maintain, and easy to use. LIW series models cover 0.5~22000L/H.

Features

Choice of solid and liquid feeding models

Fast and accurate continuous flow balance control

Working mode: 1. Constant flow control; 2. Quantitative feeding control under constant flow

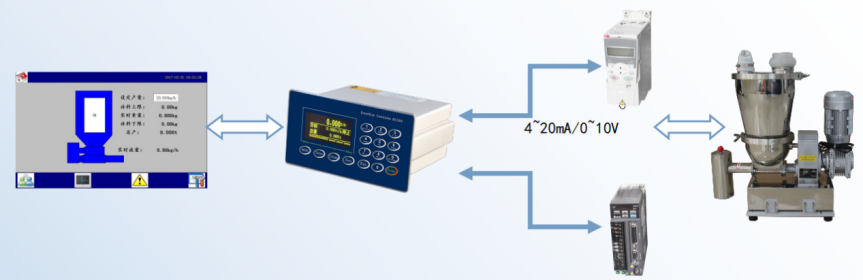

4~20mA or 0~10V adjustable output (optional)

Double closed-loop PID control system

Support remote, local switching, and manual and automatic control

Comprehensive status monitoring and chain alarm function

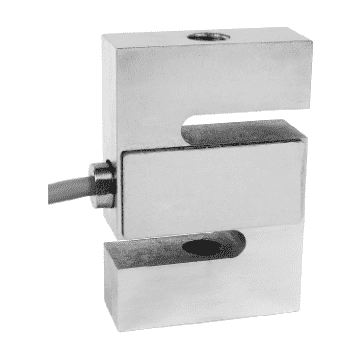

Real-time monitoring of sensor load, convenient for maintenance and troubleshooting

Fast screw replacement

Adopt 24-bit high-precision SIGMA-DELTA AD conversion chip, 300Hz effective output rate

The maximum display division number is 100000

2.71”128×64 dot-matrix OLED display; Chinese and English menu interface. The maximum display character height is 0.7”, optional touch-screen man-machine interface

Standard RS232 and RS485 dual isolated serial ports, MODBUS RTU communication protocol

Optional Profibus DP and Profinet industrial bus

Control accuracy: within ±0.2%~0.5% (according to different materials and ranges)

Feeding range: 0.5~10000kg/h (depending on different model series)

Power supply: 380VAC/50Hz

Principles and Solutions

Case 1:Independent single-component weightlessness scale control system

Case 2:Two-component weightlessness scale control system

Case 3:Multi-component weightlessness scale control system

Work Process

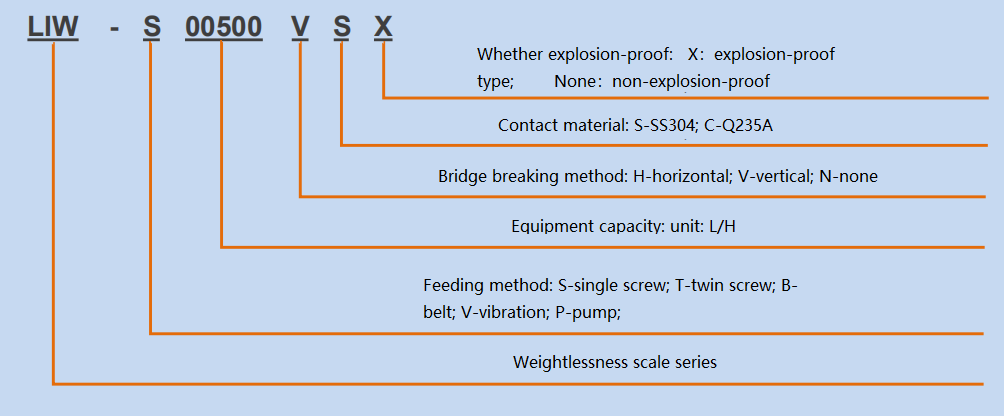

Model Specification

Order description

1. The scope of supply of this product’s standard configuration includes:

a) Mechanical structure part: scale body, metering, conveying device,

bracket, geared motor, etc.

b) Weighing control part: weightless metering controller, sensor, inverter/servo controller, low-voltage electrical components, and control box

2. The standard cable length is 10 meters, and the excess part is priced by length.

3. The weightless scale running in a single machine can be equipped with a 7′touch screen.

4. Provide before ordering: material bulk density, shape, output, and special requirements.

5. For materials with poor fluidity, samples must be submitted to the technical department of our company for verification and confirmation before the order can be signed.

Product detail pictures:

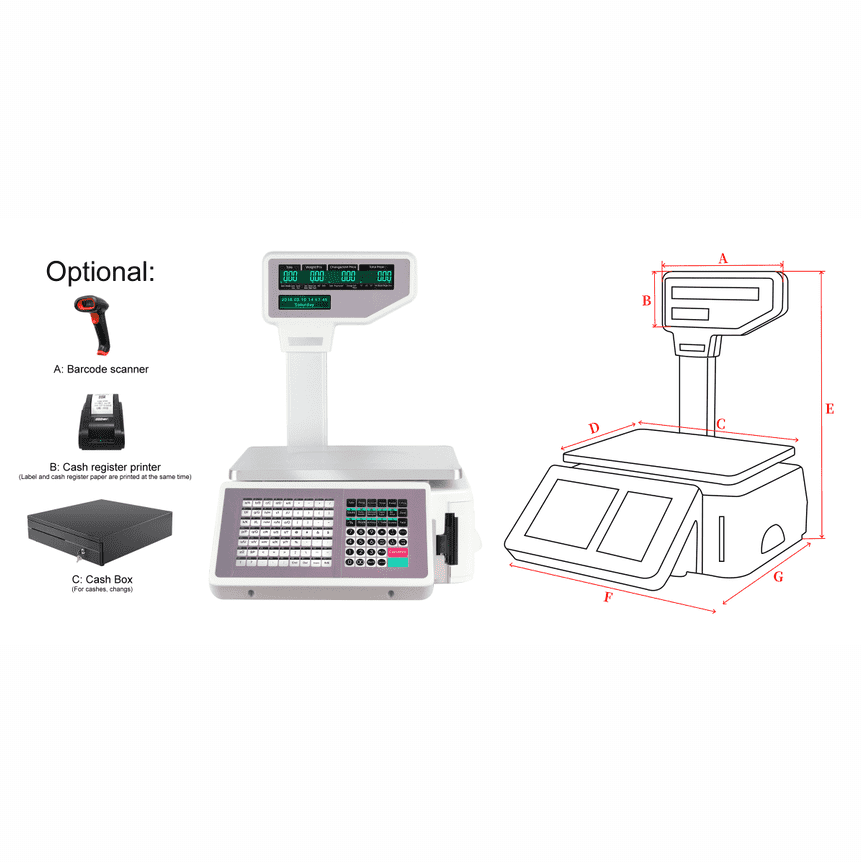

Related Product Guide:

Why is there an error in weight calibration?

New weights and their correct classification method

Our personnel are generally in the spirit of "continuous improvement and excellence", and together with the outstanding top quality merchandise, favorable price tag and fantastic after-sales solutions, we try to gain every single customer's rely on for Excellent quality Belt Weighing System - JJ-LIW Loss-In-Weigh Feeder – JIAJIA , The product will supply to all over the world, such as: panama, Malaysia, Egypt, We aim to build a famous brand which can influence a certain group of people and light up the whole world. We want our staff to realize self-reliance, then achieve financial freedom, lastly obtain time and spiritual freedom. We do not focus on how much fortune we can make, instead we aim to obtain high reputation and be recognized for our products. As a result, our happiness comes from our clients satisfaction rather than how much money we earn. Ours team will do best for you always.

We feel easy to cooperate with this company, the supplier is very responsible, thanks.There will be more in-depth cooperation.